The Rototip Team

In a world where innovation drives industry transformation, Rototip, as a deep-tech enabler, transforms intelligent custom-made parts manufacturing and agile supply chains with its visionary approach. We are excited to lead Rototip's EUR 1,000,000 funding round with the participation from Heartfelt Capital and APY Ventures, one based in Germany and backed by Porsche, and the other backed by one of the pioneering industrial zones in Turkey, home to 6,200 businesses, encompassing metal & plastic suppliers and manufacturing shops. We look forward to the opportunity to be with Rototip on their journey of innovation and ongoing success.

The Manufacturing Conundrum

The manufacturing sector struggles with unique set of challenges, especially in sourcing individually tailored parts. Whether one is a job-shop mechanic or an engineer at a satellite manufacturing firm, these hurdles persist: procuring bespoke parts, identifying suitable suppliers, and ensuring timely deliveries.

These challenges coexist with the specters of non-transparent pricing, extended lead times, variable quality, unstable supply chains, and the intricate management of numerous international suppliers. This process can be exceedingly time-consuming and operationally inefficient, leaving innovative engineers with limited time for endeavors that truly matter.

On the flip side, manufacturers face their own challenges. Local manufacturers, often equipped with large but inflexible assets, prioritize projects aligned with their existing machinery. However, this specialization can curtail their ability to fully optimize production capacity. Furthermore, these local manufacturers, lacking expertise in exporting and having limited integration into global value chains, encounter significant hurdles in maintaining customer loyalty and fostering post-delivery feedback loops.

The rise of on-demand digital manufacturing and the imperative to tackle associated challenges has led to the development of various procurement solutions in the market. Yet, these solutions often neglect quality, consistency, and reliability requirements, thereby giving rise to numerous security concerns regarding manufacturers, exports, and regulations. As the manufacturing landscape gears up for a crucial transformation, Rototip emerges with a clear mission: to spearhead this evolution and resolve the overarching conundrum.

Rototip: A Fusion of Manufacturing and Digital Prowess

In this dynamic landscape, Rototip emerges as a unifying force, set to change the way businesses source components and manufacturers operate. By redefining the manufacturing paradigm, the company introduces a two-sided platform that digitalizes supply chain operations within the manufacturing industry. Engineers worldwide benefit from this innovation, gaining access to high-quality parts for their designs—from early prototypes to finished products in mass production. With a monthly machining capacity exceeding 25,000 hours, Rototip stands as the largest manufacturer of its kind, offering a streamlined channel for sourcing hundreds of manufacturing and post-processing options.

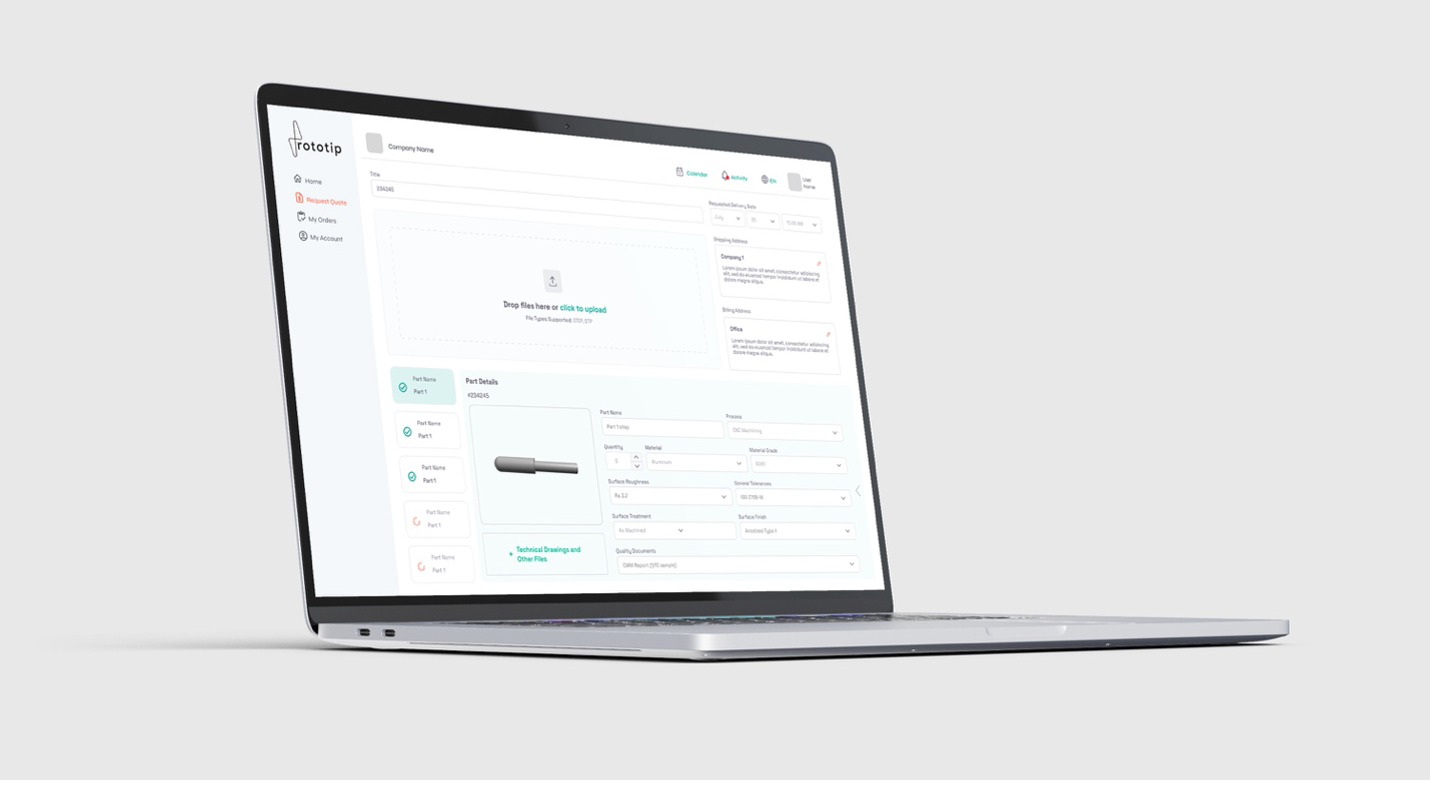

The Platform: A Closer Look

At the heart of Rototip's unique business model lies highly scalable distributed manufacturing partnerships, complemented by centralized quality control to ensure the reliability of custom-made parts. Although Rototip possesses no production capacity of its own, it functions as an aggregator, bringing together global customers with local manufacturing partners. In contrast to competitors who onboard all manufacturers, Rototip selectively collaborates with reliable manufacturers. This approach ensures manufacturing efficiency, reliability, and cost-effectiveness, all while maintaining stringent quality standards. These partners, in return, receive orders without the need for substantial investments in sales and marketing efforts, creating a mutually beneficial ecosystem, quid pro quo. With its strategic presence in the OSTIM Industrial Zone, Rototip effectively manages the intricacies of the manufacturing processes.

The platform offers an ideal solution to meet the evolving needs of businesses. As companies seek to diversify their supply chains and reduce the risks associated with offshore manufacturing, Rototip steps in to provide near-shoring solutions for European businesses. This entails leveraging a range of manufacturing techniques such as CNC machining, laser-cutting, injection molding, die casting, welding, and assembly services to source high-quality mechanical parts made from metal or thermoplastics. Customers can effortlessly save both time and money by utilizing Rototip's platform. All that's required is the uploading of their prototype CAD files, and they can rest assured that their orders will be delivered as promised, ensuring a seamless experience from order placement to doorstep delivery.

Another pivotal pillar is Rototip's innovative pricing methodology, which streamlines quotations, ensuring competitiveness and speed. The technology behind Rototip’s platform optimizes pricing for both customers and manufacturers while eliminating redundant processes. This approach not only enhances cost-efficiency but also contributes to a frictionless experience for all stakeholders involved in the manufacturing ecosystem.

Rototip takes things up a notch by contributing to sustainability. It empowers environmentally conscious purchasing decisions by revealing the carbon cost associated with the purchase. The startup also utilizes eco-friendly paper-based packaging materials and focuses on preventing defective products from reaching customers. Fewer errors translate to less waste, ultimately resulting in fewer carbon emissions.

Sustainable Packaging: Rototip's Impact on Environmental Responsibility

Fueling the Manufacturing Revolution

Competing in a USD 25 billion market within the Global Online CNC Machining Service Industry, Rototip's vision is to emerge as Europe's premier manufacturing hub. By strategically leveraging the OSTIM Industrial Zone, Rototip gains a significant competitive edge through direct engagement with local manufacturers. Additionally, Rototip has cultivated a robust presence within the European manufacturing ecosystem, building strong relationships with customers, manufacturers, and stakeholders while serving a global customer base.

Rototip is steadily attracting an expanding customer base across various geographical and industrial sectors. The company’s impressive traction not only attests to a proven business model but also reflects a high level of customer loyalty, reinforcing its potential for further growth. Leading this success are Rototip's co-founders: Galip Okan Öztürk, Onur Öztürk, Utku Gürtunca, Bart Nowak, and Samet Zeydan, who are well-equipped to lead the transformation of digital manufacturing solutions. With their extensive experience in the field, combined with planned investments in marketing activities and team expansion, Rototip is poised to achieve even greater milestones in the near future.

Innovation, Sustainability, and Growth: The Trifecta of Rototip's Journey

Our decision to invest in Rototip highlights our confidence in the company's vision, leadership, and potential for growth. As we embark on this journey together, we are excited to witness the transformative impact of Rototip as a deep-tech enabler in reshaping the manufacturing landscape. We look forward to the exciting developments that lie ahead and the shared success that awaits us.